5 Ton/Day Tube Ice Machine

Tube ice machine efficiently produces clean, uniform tube ice ideal for various applications. Crafted with food-grade materials, it ensures hygiene and safety. The automated process minimizes manual handling, making it a reliable and efficient choice for commercial use, preserving freshness and extending product shelf life.

-

Product Description

Tube ice machines constitute a specific type of ice-making equipment, categorized into two primary types: small tube ice machines and large tube ice machines. Small tube ice machines typically have a daily ice production capacity ranging from 1 to 8 tons and are predominantly constructed as standalone units. Conversely, large tube ice machines, with daily outputs spanning from 10 tons to as much as 60 tons, are mostly of a composite design and necessitate the use of cooling towers.

The ice cubes produced by these machines derive their name from their distinctive irregular, lenticular hollow tube shape. These ice cubes are renowned for their crystal-clear appearance and exceptional hardness. Characterized by their hollow cylindrical form, the ice cubes feature an inner diameter of 5mm to 15mm and a length varying between 25mm and 42mm. The outer diameter of the tube ice falls within a range of 25mm to 42mm and is offered in four standard sizes: 22mm, 28mm, 35mm, and 38mm. Additionally, customization options are available to cater to specific customer requirements.

-

Product Features

The Tube Ice Machine boasts an array of product advantages that make it a standout option for various applications. Here are the key highlights:

● Efficient Ice Production

Leveraging advanced ice-making technology, the Tube Ice Machine rapidly and efficiently produces uniform tube-shaped ice cubes. This feature renders it indispensable in commercial settings, particularly where large quantities of ice are in demand, such as hotels, restaurants, supermarkets, and more.

● Energy-Saving and Environmentally Friendly

Many Tube Ice Machines incorporate energy-efficient designs and components, minimizing power consumption and reducing environmental impact. This contributes to lower operational costs and aligns with sustainable business practices.

● Customizable Ice Sizes

The machine offers a range of outer diameters for the tube ice, including standard sizes like 22mm, 28mm, 35mm, and 38mm, with the option for customization according to customer specifications. This flexibility ensures that the ice cubes can be tailored to fit different

uses and storage requirements.● Durability and Reliability

Constructed from robust materials and designed for heavy-duty use, the Tube Ice Machine is built to last. Its reliability ensures minimal downtime and maximizes productivity, making it a cost-effective investment for businesses.

● User-Friendly Operation

Equipped with intuitive controls and user-friendly interfaces, the machine is easy to operate and maintain. This simplicity allows for seamless integration into existing workflows, minimizing training requirements and enhancing operational efficiency.

● Versatile Applications

Suitable for a wide range of industries, from food and beverage to medical and pharmaceutical, the Tube Ice Machine offers versatile solutions. Its ability to produce high-quality ice cubes makes it an ideal choice for cooling, preservation, and transportation of perishable goods.

-

Ice Tube Size

Φ22MM,Φ28MM,Φ34MM,Φ40MM is Optional

Famous brand compressor

The compressor is the heart of the ice machine and the core of the refrigeration cycle. Qianrui uses internationally renowned brands of compressors for customers to choose from. Compressors can be selected from brands such as German Bitzer, Italian Refcomp, American Copeland, and Japanese Panasonic according to product specifications and customer requirements.

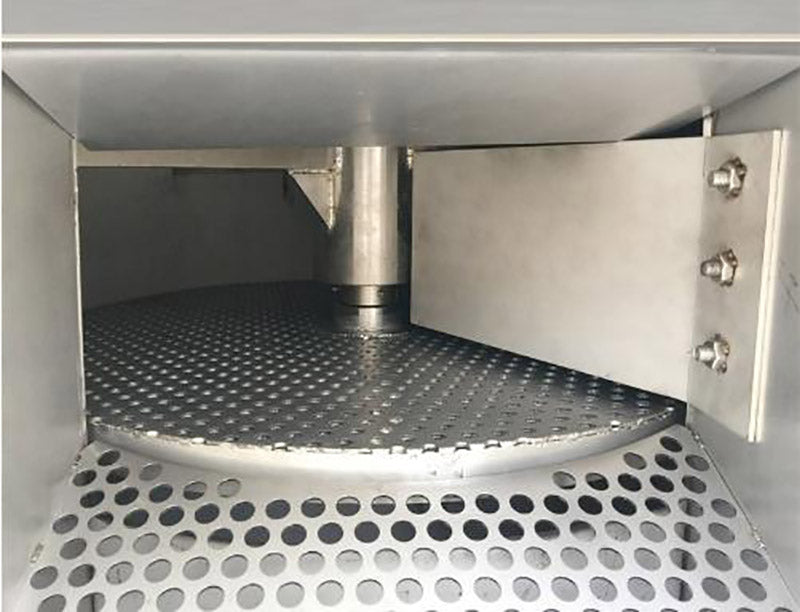

Evaporator

The Evaporator as the heart of the air-conditioning system. Employing a state-of-the-art 360° robotic welding technique, the seams are seamless and smooth, ensuring that neither refrigerant nor condensate escapes through the condenser. The robust construction of the condenser extends the operational lifespan of the system. Fabricated from SUS304 stainless steel and featuring generously sized, rounded corners throughout its design, it eliminates any hidden spots within the equipment, facilitating thorough cleaning and maintenance.

Touch Screen Controller

The touch screen interface allows seamless control of the entire system, improving user convenience. It has advanced problem detection capabilities and can continuously monitor the operating status of equipment in real time. After detecting any issues, the system will notify the user of the fault through the screen and urge immediate repair. This can prevent problem escalation and ensure uninterrupted production processes.

Ice Outlet

The ice outlet is a vital part of the machine, responsible for ejecting the ice cubes from its interior. All components that come into contact with water are made of food-grade materials to ensure the cleanliness of the ice. When the ice tube drops, the ice-cutting mechanism will activate and slice the ice tube into the preset size.

Application

Tube ice machine is ideally suited for use in various applications requiring large quantities of clean, uniform ice cubes. Consider a bustling seafood market where freshness is paramount. The machine operates continuously, producing tube ice that effectively chills and preserves the catch, maintaining its quality and shelf life. Its design ensures all ice-contacting parts are crafted from food-grade materials, guaranteeing hygiene and safety. The automated process minimizes manual handling, making it efficient and reliable for busy commercial settings.

Packing and Delivery

Provide professional, environmentally friendly, convenient and efficient packaging and transportation services.